Home :

Winning a sustainability challenge – From an environmental burden to a sustainable solution

European Composite Recycling Technology A/S (ECRTechnology) is a Danish company representing an innovative part of the creative chain from inception through to recycling concerning the use of composite materials – moving the final stage from the „grave“ such as landfill or incineration to a new „cradle“. This is achieved through components and parts delivering highest technological requirements manufactured through new production processes.

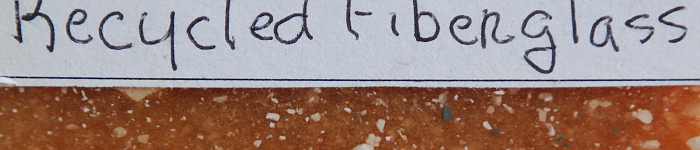

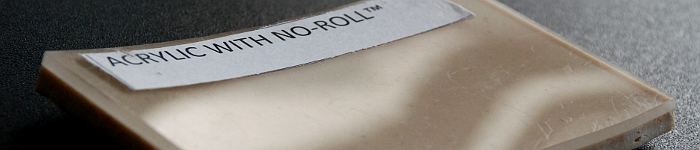

The company delivers solutions exclusively on composite materials, especially glass fiber and carbon fiber products, including even mixtures thereof.

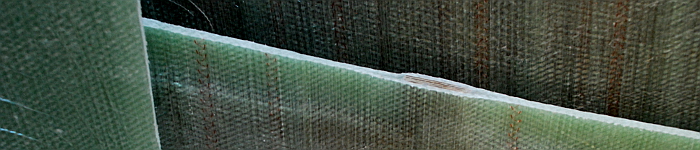

Whilst starting with the unresolved end-of-life issues of wind turbine blades in the Wind Industry, ECRTechnology now also focuses on the sustainability challenges with compound materials in the Automobile Industry.

ECRTechnology is based on a combination of proven technologies together with an innovative business concept that meets the customer’s desire to recycle their used composite materials at the same cost as invested currently in common waste disposal, in an innovative and environmentally sound manner – thereby improving the carbon footprint of the customers’ products as well as the company, reducing the resource consumption and environmental cost as well as the company’s risk profile, and increasing the environmental as well as the sustainability performance as well as, last not least, the company’s reputation.

Background:

Compound materials are one of the key production materials due to their light weight, high strength and resilience and many other key performance indicators, e.g. in the wind, aeronautic, naval and automobile industry. Due to its unique advantages glass fiber and carbon fiber materials are steadily on the rise, for years in a row now.

However, not only due to the long lifespan of the products from the industries mentioned above, the question of decommissioning and final disposal of the parts, components and products made from these compound materials remains unresolved.

Taking for example the wind industry and the recent resurgence of the debate on the disposal of redundant turbine blades – depending on the different sources in the next decade until 2020 an amount of some 42.000 wind turbines representing some 270.000 tons of compound material from the blades and nacelles are to be decommissioned and disposed of.

And as if these masses of compound material in the light of limited landfill capacities and resource shortages would not be motivation enough for a change, even more environmental benefits are to be derived from the facts that each kg of recycled glass fibre substituting virgin fiber material represents a saving of 48 MJ of Energy, as well as 2 kg CO2, 9g SOx and 3g NOx – hence a fully implemented compound material recycling could add up to savings of 12.964.800 GJ of Energy, 540.200 tons of CO2, 2.431 tons of SOx and 810 tons of NOx in the next decade for wind industry alone.

These compound material-related environmental burdens pose serious questions to an industry perceived as “green” by its purpose of renewable energy production – not even mentioning the issues of other industries such as the aeronautic, naval and automobile industry.